This article explores: Building O’Neill Cylinders in space: The role of 3D printing and autonomous construction. Find out more about 3D printing and o’Neill cylinder autonomous construction.

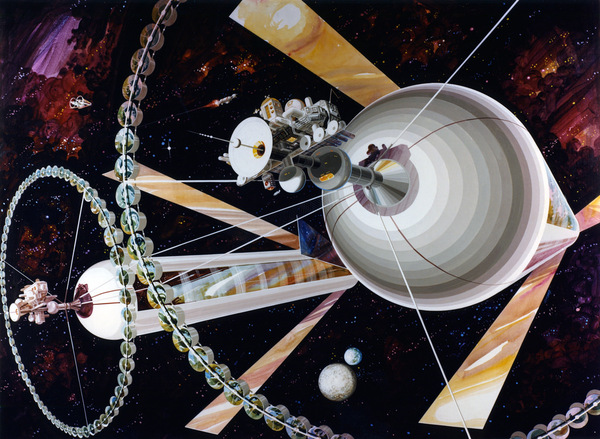

The concept of O’Neill Cylinders, massive rotating habitats capable of sustaining human life in space, has long been a subject of interest for space enthusiasts and researchers.

While the potential benefits of these structures are vast, the technical challenges of constructing them in space are significant. In recent years, advances in 3D printing and autonomous construction technologies have opened up new possibilities for building large structures in space.

This paper explores the potential of 3D printing and autonomous construction for the construction of O’Neill Cylinders in space.

We will examine the technical capabilities of these technologies, their potential benefits, and their limitations in the context of building these massive structures.

Ultimately, this paper seeks to assess the feasibility of using 3D printing and autonomous construction for the construction of O’Neill Cylinders, and to explore the potential impact that these technologies could have on the future of space exploration and colonization.

How Could 3D Printing Be Used In Space?

3D printing, also known as additive manufacturing, has numerous potential applications in space exploration and development.

Some of the ways in which 3D printing can be used in space are:

Manufacturing spare parts:

3D printing can be used to produce spare parts and tools on demand, eliminating the need to transport them from Earth. This could save time, money, and reduce the amount of cargo that needs to be launched into space.

Building structures:

3D printing can be used to construct structures in space, such as habitats, storage facilities, and other infrastructure. This could be particularly useful for long-duration space missions, such as those to Mars.

Fabricating medical supplies:

3D printing can be used to produce medical supplies and equipment, such as prosthetics and surgical instruments, which may be difficult or impossible to transport from Earth.

Creating custom objects:

3D printing can enable astronauts to create custom objects and tools to suit their specific needs and requirements, which may not be available on the spacecraft or station.

Recycling waste:

3D printing can be used to recycle plastic waste and turn it into usable materials, reducing the amount of waste generated on spacecraft.

Overall, 3D printing technology can help to increase self-sufficiency and reduce the reliance on Earth for supplies and equipment in space exploration and development.

How Is 3D Printing Used With Autonomous Construction?

Autonomous construction refers to the use of robots and other automated systems to build structures without human intervention.

3D printing can play an important role in autonomous construction by enabling the production of complex shapes and structures without the need for manual labor.

Here are some ways that 3D printing is used with autonomous construction:

Robotic 3D printing:

Robotic arms can be used to perform 3D printing, allowing for the creation of complex shapes and designs. The robot can be programmed to move along a predefined path, laying down material layer by layer to create the desired structure.

Large-scale 3D printing:

3D printing can be used to create large-scale structures such as buildings or bridges. By using 3D printing, structures can be built with less material and in less time than traditional construction methods.

On-site fabrication:

With 3D printing technology, it is possible to fabricate parts and components on-site, reducing the need for transportation of materials and increasing the speed of construction. This is especially useful in remote or difficult-to-access locations.

Integration with other autonomous systems:

3D printing can be integrated with other autonomous systems such as drones, robots, and sensors to create a fully automated construction process.

For example, drones could be used to survey the construction site and provide data to the 3D printer, allowing it to adjust its printing path to account for any changes in the environment.

Overall, 3D printing can help to enable autonomous construction by reducing the need for manual labor and enabling the creation of complex structures.

Can Autonomous Construction Be Used For Building O’neill Cylinders?

Autonomous construction could potentially be used for building O’Neill Cylinders, which are large, rotating space habitats that could support human settlements in space.

The construction of an O’Neill Cylinder would involve assembling many large, complex components, and autonomous construction could be used to build these components with greater precision and efficiency than traditional construction methods.

Here are some ways that autonomous construction could be used for building O’Neill Cylinders:

Large-scale 3D printing:

As mentioned earlier, 3D printing technology can be used to create large-scale structures such as buildings or bridges. In the case of an O’Neill Cylinder, 3D printing could be used to fabricate the large structural components of the habitat, such as the shell and support beams.

Robotic assembly:

Once the structural components have been fabricated, robots could be used to assemble them into the final structure of the O’Neill Cylinder. These robots could be programmed to work together in a coordinated manner, using advanced sensing and control systems to ensure that the components are assembled with precision and accuracy.

Autonomous inspection and maintenance:

After the O’Neill Cylinder is completed, it would need to be regularly inspected and maintained to ensure that it continues to function properly. Autonomous robots could be used to perform these tasks, using sensors and other advanced technologies to detect any problems and make repairs as necessary.

On-site fabrication:

3D printing technology could be used to fabricate the various components of the cylinder, such as the structural framework, interior walls, and living quarters. These components could be printed on-site, reducing the need for transportation of materials and enabling construction to take place in remote or difficult-to-access locations.

Integration with other autonomous systems:

3D printing and robotic systems could be integrated with other autonomous systems such as drones and sensors to create a fully automated construction process. Drones could be used to survey the construction site and provide data to the 3D printer and robots, allowing them to adjust their printing and assembly paths to account for any changes in the environment.

Overall, while there are still many technical and logistical challenges that would need to be overcome to build an O’Neill Cylinder, autonomous construction could be an important tool for making this ambitious project a reality.

Can A 3D Printer Work In Zero Gravity?

Yes, a 3D printer can work in zero gravity. In fact, 3D printing technology has been tested and used on the International Space Station (ISS) since 2014.

The 3D printing process in zero gravity is slightly different from that on Earth due to the absence of gravity.

Without gravity, the melted material from the 3D printer’s nozzle does not flow downward and can create unintended shapes. This issue can be addressed by using a modified 3D printer that is specifically designed for zero gravity environments.

One way to mitigate the effects of zero gravity is to use a 3D printer that uses a process called fused filament fabrication (FFF), also known as fused deposition modeling (FDM). This involves melting a thermoplastic material and depositing it layer by layer to create a 3D object.

In zero gravity, the melted material can become detached from the nozzle and create “floating blobs” of plastic. To address this, a modified FFF 3D printer can be used, which uses a heated chamber to keep the material from floating away.

Another way to address the challenges of 3D printing in zero gravity is to use a different type of 3D printing process, such as stereolithography (SLA) or selective laser sintering (SLS), which use a liquid or powdered material that is cured or fused using a laser or other energy source.

These processes are less affected by the lack of gravity and can be used to create complex shapes and structures in space.

Overall, 3D printing technology can work in zero gravity with some modifications and adjustments to the printing process. It offers a promising way to manufacture parts and structures in space and reduce the need for resupply missions from Earth.

References for: “Building O’Neill Cylinders in space: The role of 3D printing and autonomous construction”

“The High Frontier: Human Colonies in Space” by Gerard K. O’Neill – This classic book discusses the potential for autonomous construction techniques in building O’Neill cylinders.

“Space Settlements: A Design Study” by NASA – This study, conducted in the 1970s, examines the potential for autonomous construction techniques in building O’Neill cylinders.

“Autonomous Construction in Space: Robotics for On-Orbit Satellite Servicing” by Andrew Ogilvie, Justin Allport, Michael Hannah, John Lymer – This paper examines the potential for autonomous construction techniques in building space infrastructure, including O’Neill cylinders.

“Advanced manufacturing for space applications” by Andrew Norman, Shumit Das, Thomas Rohr & Tommaso Ghidini – This paper examines the potential for 3D printing technologies in building space infrastructure, including O’Neill cylinders.

“3D-Printing Lunar and Martian Habitats and the Potential Applications for Additive Construction” by M C Roman, Michael Fiske, Shadi Nazarian, Melodie Yashar – This paper discusses the potential for 3D printing technologies in building space infrastructure, including O’Neill cylinders.

“Space Manufacturing 3: Proceedings of the Fourth Princeton/AIAA Conference” edited by John H. Hoffman and Frederick A. Candelaria – This conference proceedings book includes papers on the potential for autonomous construction techniques in building space infrastructure, including O’Neill cylinders.

“Space Settlement Basics” by Al Globus – This book examines the potential for autonomous construction techniques in building O’Neill cylinders, including the use of 3D printing technologies.

“The Case for Mars” by Robert Zubrin – This book includes a discussion of autonomous construction techniques in building space infrastructure, including O’Neill cylinders.

“3D Printing and Additive Manufacturing: Principles and Applications” by Chee Kai Chua and Kah Fai Leong – This book includes a chapter on the potential for 3D printing technologies in building space infrastructure, including O’Neill cylinders.

“The Mars Society’s Marspedia” – This online resource includes a section on autonomous construction techniques in building space infrastructure, including O’Neill cylinders, and the potential role of 3D printing technologies.

‘Building O’Neill Cylinders in space: The role of 3D printing and autonomous construction’ is one important topic in our series exploring the role of O’Neill Cylinders in space colonization.

Read more about these topics by following the links below:

Republished by Blog Post Promoter